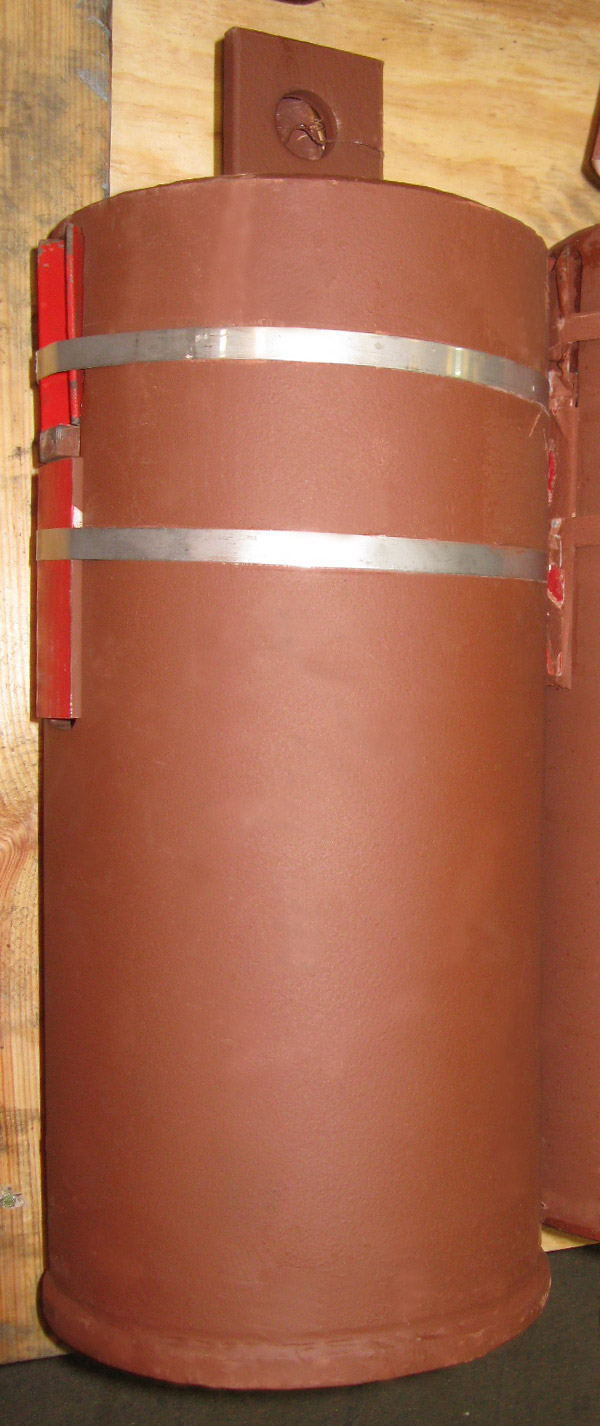

251 variable furnace springs were designed and fabricated for fertilizer production at a chemical plant in Virginia. The furnace cans are carbon steel and painted with red-oxide primer to avoid any potential hazards where exposed to high temperatures. This project included figures: PTP-1-120, PTP-2-150, PTP-2-180, PTP-4-100 and PTP-4-200 variable furnace springs with operating loads ranging from 1,042 lb. to 15,512 lb. A load test on all variable springs was conducted prior to shipment.

251 variable furnace springs were designed and fabricated for fertilizer production at a chemical plant in Virginia. The furnace cans are carbon steel and painted with red-oxide primer to avoid any potential hazards where exposed to high temperatures. This project included figures: PTP-1-120, PTP-2-150, PTP-2-180, PTP-4-100 and PTP-4-200 variable furnace springs with operating loads ranging from 1,042 lb. to 15,512 lb. A load test on all variable springs was conducted prior to shipment.

Blog Category: ENGINEERED SPRING SUPPORTS

Variable Springs with Guided Load Columns and PTFE Lined Pipe Saddles

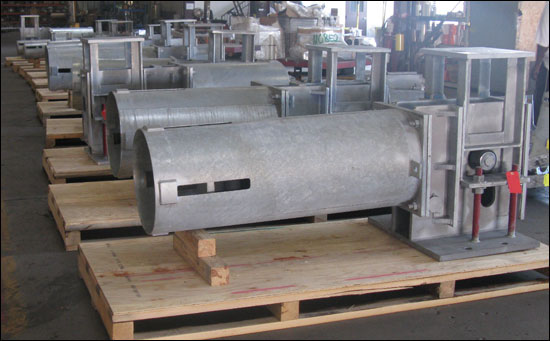

These F-type variable spring supports are fabricated from carbon steel with a hot dipped galvanized finish and designed with guided load columns to provide stability for minimum lateral movement. The fig. 46 pipe saddles are also fabricated from carbon steel with a HDG finish and lined with PTFE, 25% glass filled material. The pipe saddles are designed for 8″ to 36″ diameter pipe sizes, and the entire assembly is 50″ in height. These variable-saddle support assemblies are capable of supporting up to 22,300 lb. and 1″ vertical movements. We performed standard spring loading tests and a Q.C. inspection prior to shipping to an offshore oil and gas platform near Malaysia.

Read MoreStock Upthrust Constants Modified with an Auxillary Platform

These 200 U-Type constant spring supports were modified to increase their installed height by adding a secondary plate and angles, which will be welded to the structural beam. The constants range in size from 25″ to 27″ in height, 52″ to 67″ in length, and 25″ in width. Their load capacities range from 10,300 lb. to 13,000 lb. with vertical movement ranging from 3″ to 4-1/2″. All constants were fabricated from A-36 carbon steel, and went through standard load and travel testing per MSS Standards prior to shipment.

Do you have a similar application that requires upthrust constants? Get pricing today!

U-Type Constant Springs Custom Designed for Large Travel for an Oil Refinery

These figure 200 U-type constant springs were fabricated from A-36 carbon steel and range in size from 30-1/2″ to 41″ in height, 25″ to 31″ in width, and 68″ to 80″ in length. These are horizontal constants designed to support piping from below where the base plate is bolted directly to the top of the steel or the foundation using anchor bolts. Loads range from 9,000 lb. to 42,000 lb., and vertical movements range from 6″ to 11″. All the constants went through standard load and travel testing per MSS Standards prior to shipment.

Want to learn more about constant springs? Instantly view a recording of a past webinar.

Read MoreF-type Variable Spring Support with a Stainless Steel Wire Rope Isolator

This F-type variable spring support was customized with a wire rope isolator for a facility located in Canada. The variable spring was designed for a load of 12,000 lb. The wire rope isolator is essentially a 1.25″ diameter stainless steel rope looped eight times between two chemically conversion coated aluminum alloy retaining bars. The wire rope isolator is effective in vibration isolation and energy absorption.

Need a similar support? We’d be happy to serve your needs!

Variable Spring Supports for a Gas Storage Facility in Abu Dhabi

A total of 90 variable spring supports were designed and manufactured to support pipe lines in a gas storage facility in Abu Dhabi. The pictures above show PTP-4 Double Spring B-Type, PTP-6 Triple Springs B-Type, PTP-1 Triple Springs D-Type, and PTP-4 Double Springs F-Type, (also known as F-Cans). Load capacities range from 1,000 lb. to 45,000 lb., and movements range from 3/8″ to 3″. A two-layer custom paint was applied over the hot-dip galvanized finish to protect against a severely corrosive environment. Travel stops were chained to the spring can housing, so they can be reused during plant shutdowns. Load and quality assurance tests were performed on all the supports prior to shipment.

Need variable spring supports for your piping system? Get pricing today.

Custom Designed Variable Spring Supports with Stainless Steel Slide Plates

This custom designed variable spring assembly is comprised of a standard PTP-1-160 type F variable spring with a supplementary extension and load flange with a stainless steel slide plate. The variable is fabricated entirely from carbon steel with a hot-dipped galvanize finish. The extension is schedule 40 pipe, 8″ in diameter and 12-5/16″ in height. The slide plate is fabricated from A240 grade stainless steel and is welded to the top of the load flange. This support will be used underneath a 16″ diameter pipe with a dummy leg. It is designed for 1/16″ vertical travel and 1/8″ horizontal travel for an oil refinery in Algeria.

Do you require custom variables or slide plates for your piping system? Get pricing today!

Constant Spring Supports Designed with Special Lugs for Connecting to a Trolley

These PT&P 200 series constants are fabricated from A36 carbon steel. The 200-A constants measure 18.5″w x 20″H x 65″L and will support a 22,200 lb. load. They are modified to avoid interference with the structure by shortening the frame. The 200-C constants measure 18.5″w x 29″H x 80″L and will support a 32,000 lb. load. The constants have specially fabricated lugs to allow for a 3 ton trolley to connect with it.

Do you have a need for constants in a current or upcoming project? Let us price them for you!

G-Type Variable Spring Support Assemblies for an Expansion Project at an Oil Refinery

PTP-2 Type-G variable spring support assemblies were designed and fabricated for an expansion project at an oil refinery. The G-type spring is comprised of two standard variable spring housing-coil subassemblies joined together with an intermediate bridge assembly. The bridge assembly is customized to match existing site conditions, which allows for use in applications with limited space or interferences. This particular assembly was provided with extra large channels because the specified C-C dimension of 59″ exceeded the maximum (48″) of our standard G-type variable springs. The housings, internal components and channels were fabricated from carbon steel, and spring steel was used for the coils. The assembly was designed for a total operating load of 24,014 lb. with a design travel of 0.76″ upward.

PTP-2 Type-G variable spring support assemblies were designed and fabricated for an expansion project at an oil refinery. The G-type spring is comprised of two standard variable spring housing-coil subassemblies joined together with an intermediate bridge assembly. The bridge assembly is customized to match existing site conditions, which allows for use in applications with limited space or interferences. This particular assembly was provided with extra large channels because the specified C-C dimension of 59″ exceeded the maximum (48″) of our standard G-type variable springs. The housings, internal components and channels were fabricated from carbon steel, and spring steel was used for the coils. The assembly was designed for a total operating load of 24,014 lb. with a design travel of 0.76″ upward.

Want to learn more about variable springs? Watch an instant recording of a past variables webinar.

New Spring Sizing Calculator

Don’t know your cold / installed load? Use our new web-based spring sizing calculator to find all the springs that can fit your design parameters.