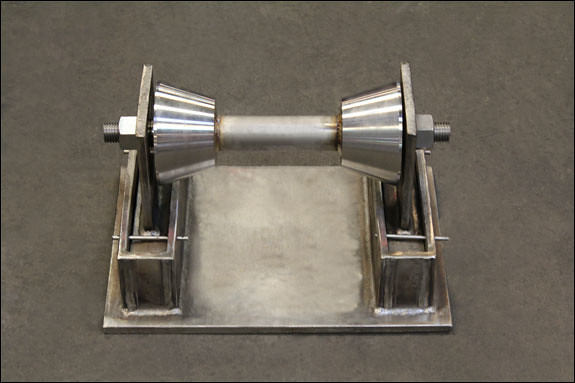

Compact Disc Spring Support Designed for a Heat Exchanger Application

In this application, the heat exchanger (vertical vessel), has thermal movement of 1/4″, vertically. As it expands thermally, the vessel lifts off its support structure and additional forces at the vessel’s lower nozzle are created. With many heat exchangers, as well as other process equipment, the space between the support structure and equipment is restricted. In this case, the space between the cantilever clamp attached to the vessel and the support structure is limited to only 5.1″. This lack of space is unsuitable for placing the conventional spring supports which require more space.

The Compact Disc Spring support is designed to support large loads in small confined spaces with limited thermal movement (from 0 to 3/4″). By supporting the vessel with Disc Springs, the thermal movement is allowed (or relieved), which helps reduce the excessive loads and local stress on the nozzles. This results in compliance with the ASME Piping and Vessel Codes. Due to a corrosive chemical plant environment, the two Compact Disc Spring supports were supplied with engineered 17-7PH Stainless Steel Belleville Disc Springs to combat corrosion.

Read More