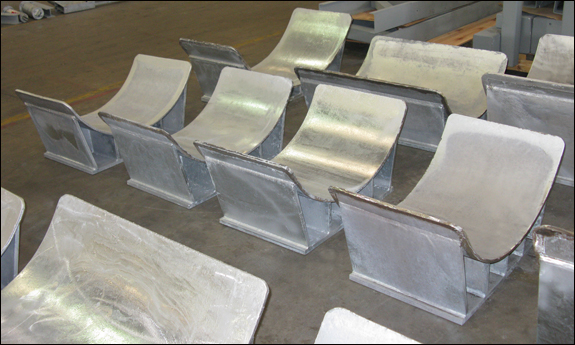

Piping Technology designed hot shoes with sliding bases for a power plant in Mississippi. The assemblies will be installed on 28″ diameter pipe and include 1-1/2″ thick calcium silicate insulation. Manufacturing fabricated these supports from galvanized carbon steel with a polyethylene base. They are capable of an operating load of 7,200 lb., temperatures up to 1,200 degrees F and an axial movement of +/- 4-1/2″. The shipment was met three days prior to the critical field need date.

Read MoreBlog

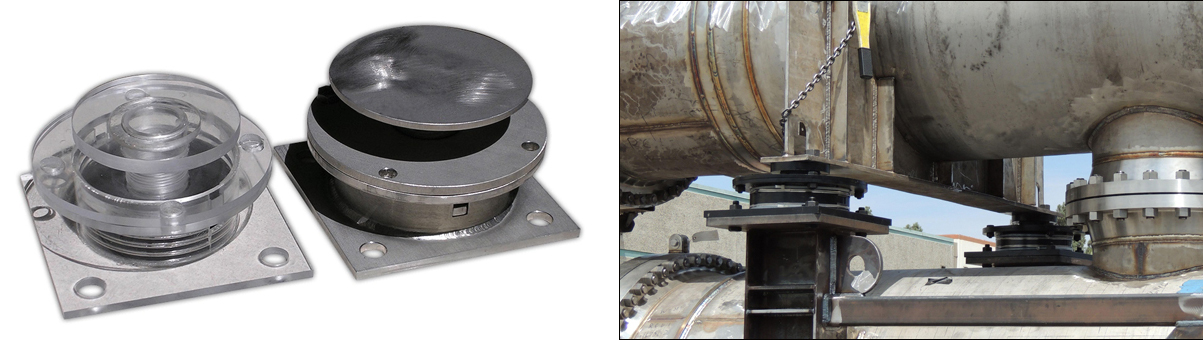

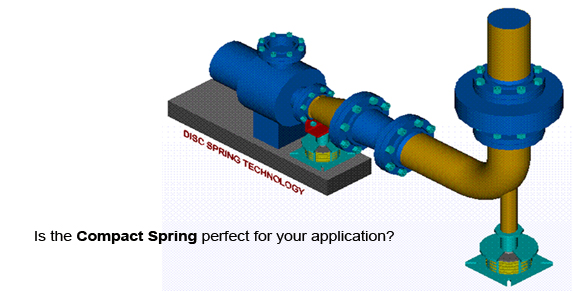

PT&P partners with Disc Spring Technology to offer you the Compact Spring Support

The compact spring is ideal for applications with large loads and limited space.

The compact spring is ideal for applications with large loads and limited space.

– Minimizes excessive loads on sensitive equipment

– Same load for smaller working range while consuming 25-50% less space

– Ideal for locating under equipment flanges

– Reduces design time, maintenance cost and accidents

>> Get a quote now or email us your questions at info@pipingtech.com

These springs are the solution for satisfying excessive nozzle loads for load sensitive equipment, such as pumps, compressors, turbines, blowers, heat exchangers, pressure vessels and storage tanks. In addition, the entire spring support can be made from corrosion resistant stainless steels or other suitable alloys making it ideal for combating aggressive environments like seawater, marine air and harsh chemicals.

View the DST Catalog for more details

Read MoreFabricated Pipe Shoes Designed for Large Dia. Piping in LNG Facility

A total of forty-five fabricated pipe shoes were designed for large diameter piping in an LNG facility. The saddles are fabricated from 516 Grade 70 carbon steel to withstand low temperatures and have a hot-dipped galvanized finish. They were designed for 30″, 36″ and 48″ diameter pipe sizes.

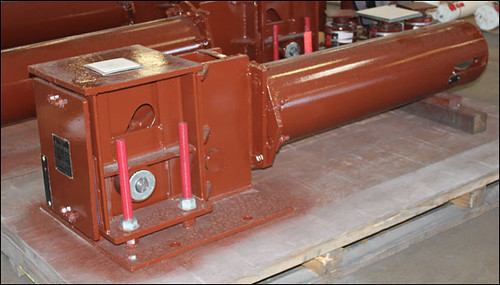

Read MoreF-type Variable Spring Supports Designed for a Petroleum Facility

PT&P designs thirty F-type variables spring supports for a petroleum facility in Canada. The springs are fabricated from carbon steel and with a hot-dipped galvanized finish. The assemblies are internally guided and have a 3,455 lb. operating load. A standard travel test was conducted on the variables prior to shipment.

Read MoreNew Customer Portal to Track Your Jobs

- View when your order was entered into the Customer Portal

- See when it was sent to the shop

- Look over the line item details of your order

- Check when your order has been shipped

- Access your carrier and tracking information

- Download Bill of Materials and scanned shipping documents for any shipment

- Export your information into a .CSV file

- See the “shop progress” graphs that show which operations are completed

View more information at: https://stg-httpspipingtechcom-stagingdev.kinsta.cloud/resources/technical-bulletins/

Read More1,328 Hold-Down Pipe Clamp Supports Designed for Insulated Pulsating Gas Pipelines

PT&P fabricated 1,328 hold-down pipe clamp assemblies for insulated pulsating gas pipelines. They are fabricated from carbon steel and designed with PTFE slide plates and kinetics-vibroisolating pads. The hold-downs are designed for 2″ to 8″ diameter pipes and operating temperatures ranging from -20°F to 750°F.

Read MoreG-Type Variable Spring Supports Designed for a Paper Manufacturing Plant

PT&P designed G-Type variable spring supports for a paper manufacturing plant in Minnesota. The variables are comprised of two standard spring housing coil subassemblies joined together with an intermediate bridge assembly. The bridge assembly is customized to match existing site conditions which allows for use in applications with limited space or interferences. The variables are fabricated from carbon steel with a hot-dipped galvanized finish. The assemblies were designed for a total operating load of 1,348 lb. with an upward design travel of 0.8013″. Each assembly underwent a standard load test prior to shipment.

Read MoreU-Type Constant Spring Supports Designed to Support Ducts in an Acid Plant

U-Type constant spring supports were designed to support ducts in an acid plant. The constants are fabricated from carbon steel, galvanized and painted for extra protection against corrosion. The U-type constants are designed to support piping from below. The base plate is 25-7/8″ wide and bolted directly to the top of the steel or floor. The assemblies measure 84″ in length and 22-1/2″ in height. They only have vertical movement subjected by 6-1/2″ total upwards travel and are capable of supporting a 13,489 lb. load. The constants underwent standard spring testing prior to shipment.

Read MoreVariable Spring Supports Designed for a Coker Unit in an Oil Refinery

PT&P designed and fabricated D-type variable spring supports for a coker unit in an oil refinery in the UAE. The variables are designed for a special pipe diameter of 4-3/4″. The cans are fabricated from electro-galvanized carbon steel, and the springs are coated with an electrophoretic epoxy coating. The variable springs are designed for 2.79″ of upwards movement, 300 lb. at 81°F. Standard load test and a spring rate test was performed prior to shipment.

Read MoreAdjustable Pipe Saddle Supports Designed for a Hydrocracker Project

PT&P supplied sixty-nine adjustable pipe saddle supports for a hydrocracker project in an oil refinery. The supports will be installed under a trunnion and range in heights from 12″ to 48″. They have 8″ diameter top plates, and are designed to support pipes from 2″ to 8″ in diameter. The supports are fabricated from carbon steel and consist of schedule 40 and 80 pipes and concentric reducers. The operating temperature for these custom designed saddle supports is 750″F. Each assembly was inspected by Q.C. prior to shipment.

Read More