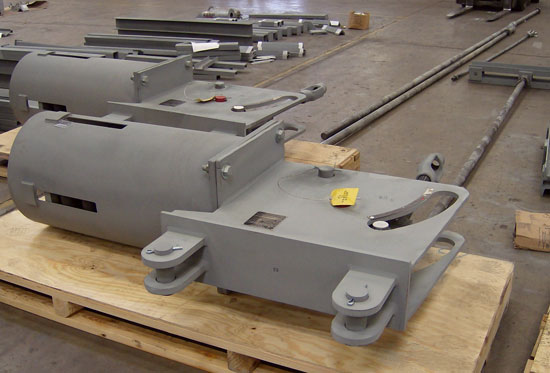

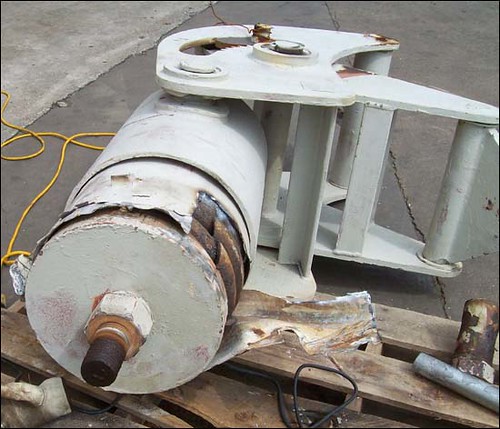

PT&P manufactured 72″ dia. insulated supports for temperatures as low as -260°F. The insulation is multi-layered comprised of polyurethane foam with a density of 20 PCF, a vapor barrier, an aluminum metal jacket, and acoustic pads. The acoustic pads are installed around the cold shoe to absorb vibration. The base and bearing plates are fabricated from carbon steel. The shoes will be used to support and insulate piping in a receiving & regassification plant and refinery.

Do you require cryogenic insulated supports in your piping system? Get pricing now!