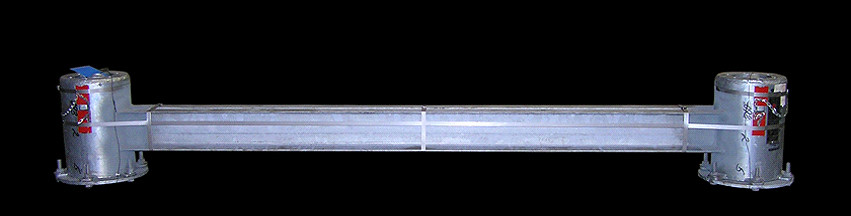

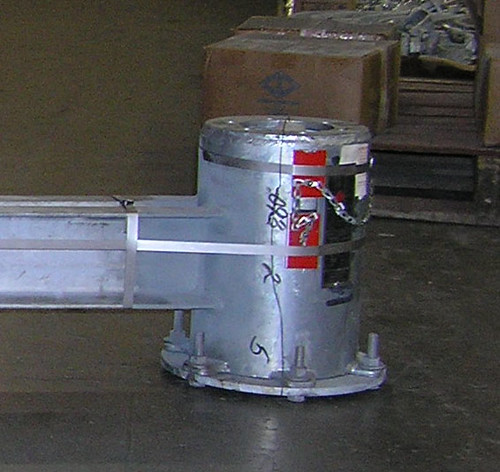

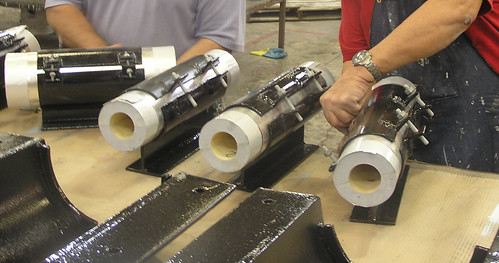

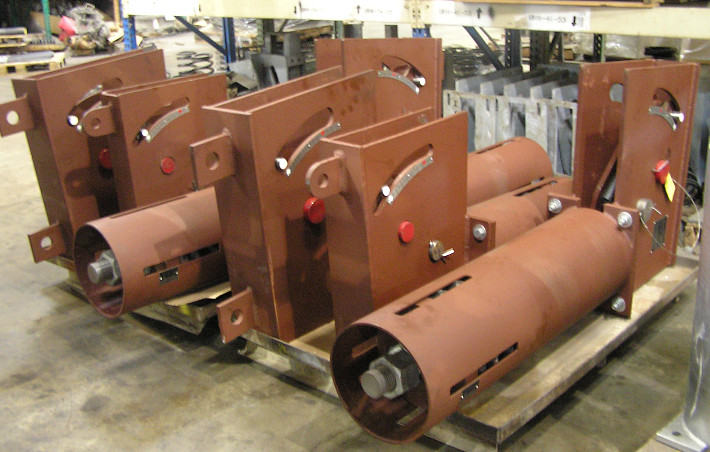

Piping Technology & Products, Inc. fabricated a Cantilevered Canopy for the entrance of an International State Department building. The Canopy was fabricated using ten 20-foot long girders. These girders were connected by sixty-three structural steel members. Together, they formed the 80-foot width of the Canopy. The wooden sheathing and architectural cladding that is supported by the canopy’s inner steel structure was installed at the construction site.

The fabricated girders and structural members combined weight exceeds 33,000 lb.

Piping Technology & Products also supplied the steel framing that supports the sheathing and cladding, roof drains and piping installed inside the canopy.

Want to learn more about the miscellaneous structures we provide? Watch a webinar today!