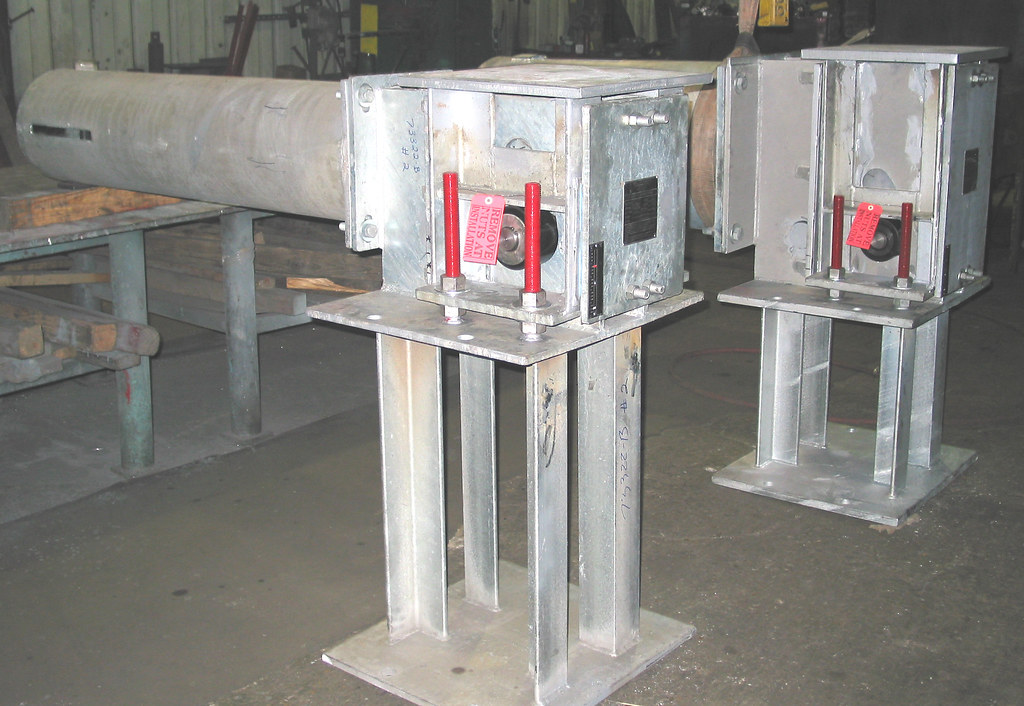

Piping Technology & Products, Inc. custom designed and fabricated PTP-100 type U and PTP-100 type A constants. The PTP-100 type U constants are designed for operating loads of up to 17,000 lbs. and a travel range of 3.5″. They are fabricated from A36 carbon steel with dimensions of 32″x48″x13″. The PTP-100 type A constants are fabricated from the same material and measure 39″x42″x14″. The type A constants are designed to support loads up to 25,000 lbs. and enable downward travel of up to 4″. Standard load testing was performed to ensure product quality before shipping.

Do you require constant springs for your piping system? Get pricing today!