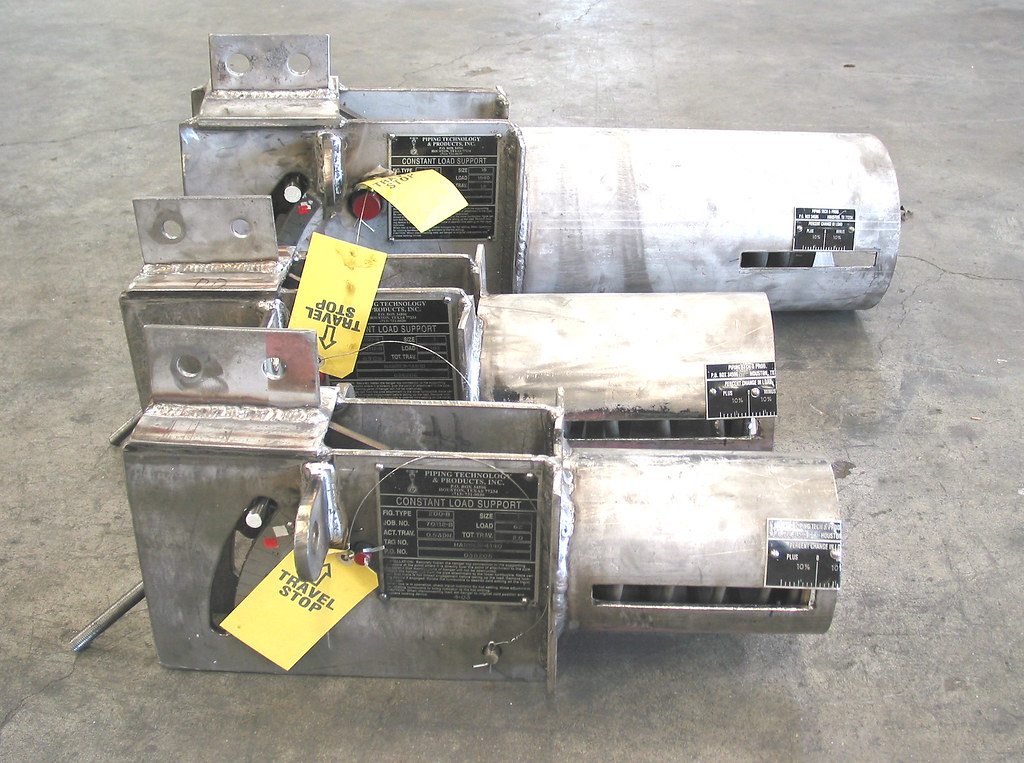

Within a two-week span, PT&P designed and fabricated eight Stainless Steel, grade-304, types B & E Constants for a marine plant. These constants have a travel of 1 1/2 – 5″ and are specified to carry 50 – 1540 lbs load. Stainless steel was requested due to the corrosive nature of the environment. PT&P also manufactured nine Carbon Steel types B & E Constants for this project.

Do you require constants in your current or future project? Let us price them for you today!

Read More