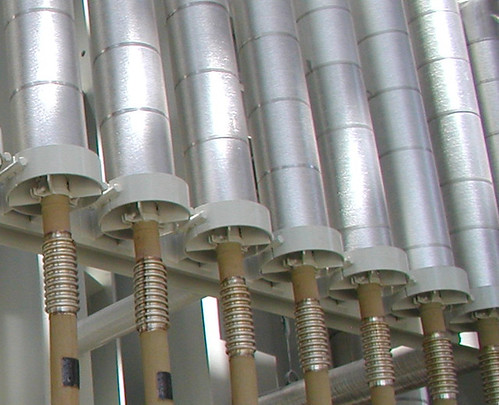

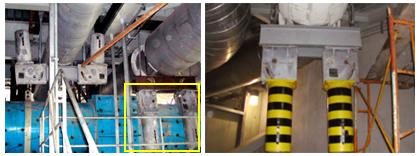

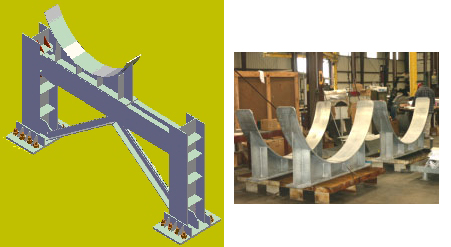

Piping Technology & Products, Inc. designed and manufactured hundreds of hanger rods and clevises for a 1,250 MW natural gas combined cycle facility in Mississippi.

The rod and clevis components were made of various alloys (800H, F91, 316H, SA-387 Gr. 22) and ranged in sizes from 2″ to 4″ diameter. Taking into account the surrounding environment’s conditions, engineers designed the rods and clevises so that they can endure temperatures escalating to 1430º F. For the duration of a pull test conducted, the clevises and rods sustained loads up to 152,000 lbs. and there were no discrepancies.

Are rods and clevises on your checklist for an upcoming project? Request a quote today!