|

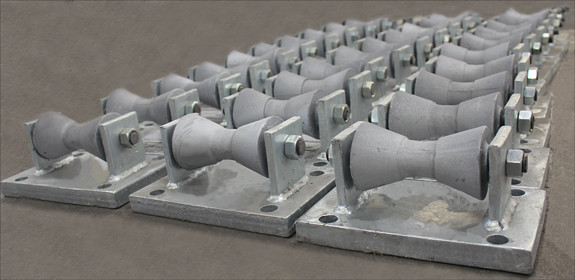

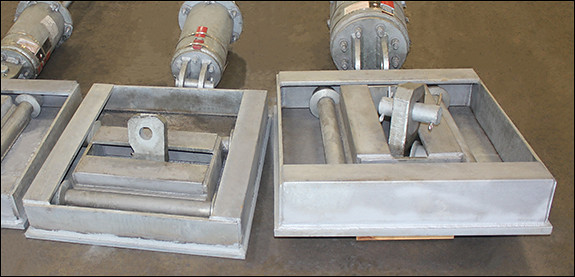

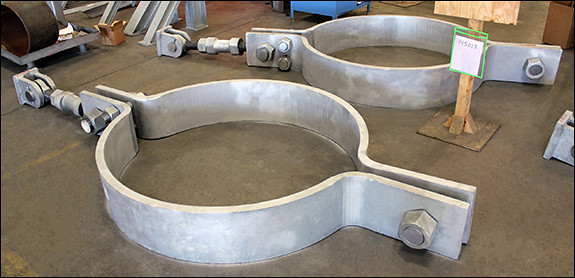

Piping Technology & Products custom designed these structural supports to provide base support for pipes at a liquid natural gas (LNG) facility in Louisiana. The supports are fabricated from carbon steel with a hot-dipped galvanized finish. Sizes range from 6″ x 12″ to 6″ x 18″ and all supports underwent a quality control inspection prior to shipment.

Read More

This presentation will cover Pipe Clamps, including Hold-Down Clamps, Riser Clamps, Clevis Hangers, Yoke U-Bolt Clamps and Structural Supports. Learn how the appropriate type of pipe support is chosen based on the different design conditions. Find out how Finite Element Analysis is used in the design process and view the custom pipe supports designed for extreme applications.

This presentation will cover Pipe Clamps, including Hold-Down Clamps, Riser Clamps, Clevis Hangers, Yoke U-Bolt Clamps and Structural Supports. Learn how the appropriate type of pipe support is chosen based on the different design conditions. Find out how Finite Element Analysis is used in the design process and view the custom pipe supports designed for extreme applications.