Thirty-six custom designed pipe saddles were created for a power plant in Mississippi. These 20″ W x 72″ L x 30″ H saddles were made with carbon steel with PTFE slide plates. These pipe saddles were designed to support a load of 55,000 lb. and will be applied to fluid bed duct supports.

Read MoreBlog Category: SUPPORT ASSEMBLY COMPONENTS

Heavy Duty Yoke U-Bolt Pipe Clamps for a Continuous Catalyst Regeneration Plant

These custom heavy duty Fig. 43 yoke u-bolt pipe clamps are designed for manifold piping in a Continuous Catalyst Regeneration plant in Mexico. The yoke clamps are for a 36″ diameter pipe size and are fabricated from A240 Grade 316 stainless steel. They are designed to support a load of 33,731 lb. and temperatures up to 1100°F. PT&P supplied a total of 16 assemblies, comprised of yoke u-bolt clamps and E-type constant springs, for this project.

Do you need yoke u-bolt clamps or constants? We would be happy to provide you with a quote today.

Adjustable Pipe Saddle Supports Designed for a Booster Pump Station Rehabilitation Project in Florida

PT&P designed adjustable pipe saddle supports fabricated from A240 Gr 304 stainless steel, for a Booster Pump Station Rehabilitation Project in Florida. The pipe saddles are stanchion type supports designed for 10″ and 16″ pipe sizes, and can be vertically adjusted +/- 3″ by turning the middle section of the seamless pipe.

Looking for adjustable pipe saddles for your application? We’d be happy to serve your needs!

Custom Designed Elevated Hold-Down Clamp Assembly Fabricated for a 54" Suction Line in a Gas Plant

The 54″ suction line carrying gas to a gas compressor at a rate of 1.7 million lb./hr. developed a severe vibration. The deflections in the line were up to 3/4″ and it was fully observable during operation.

PT&P designed and manufactured a special elevated hold-down clamp, including a unique laminated vibration dampening lining. The entire pipe hanger assembly stands 22′ high and is coated with a carboline zinc finish. After installation and resumption of operations, the vibrations are now almost imperceptible.

Want to learn more about pipe clamps? View a recording of our pipe clamp webinar now!

Read MoreLarge Custom "Sling" Support and Horizontal Traveler Assemblies for an Oil Refinery

Three custom “sling” support assemblies fabricated from stainless steel were designed for an oil refinery in Louisiana. The assemblies are comprised of a 79.25″ diameter custom saddle support and two horizontal travelers (Fig.270 PTP-4). They are capable of loads up to 44,000 lb., and were designed, fabricated and shipped in four weeks for expedited delivery.

Do you have a requirement for a large custom designed product? Get pricing today!

Structural Supports Coated with Red Oxide Primer for a Power Plant

The structural pipe supports are fabricated from carbon steel and coated with red oxide primer. The structural steel will be stored in a warehouse for several months while the power plant is being built. Due to the plant’s location along the United States East Coast, the use of the red oxide primer was selected. Also, modifications were made to our standard “insulation saddles” to allow for a higher load capacity; which can be seen in the foreground of the image above.

Do you require replacement or additional structural supports in your plant? Get a quote today!

Custom Chrome-Moly Three-Bolt Pipe Clamps for a Power Plant

The pipe clamps are manufactured from 2″ thick by 10″ wide Chrome-Moly (A387 Gr. 22) bar stock and alloy (A 193 Gr. B7) bolting of 2-3/4″ diameter throughout. They are designed for an operating temperature of 1065°F with a maximum design load rating of 35,000 lb. The pipe clamps will be used to support 24″ diameter pipe in a power plant.

Want to learn more about pipe clamps? Instantly view a past pipe clamp webinar!

22" Dia. Riser Clamps for a Power Plant

All four riser clamps are manufactured from A-36 carbon steel plates and are coated with red oxide primer for rust prevention. They are 22″ in diameter with each plate measuring 2″ thick by 12″ wide by 65″ long. Each riser clamp is capable of supporting loads of up to 38,000 lb. and will be used in a power plant to support “downcomer” lines.

Do you see a need for riser clamps in your current or upcoming project? Let us price them now!

Billet Style Clevises & Turnbuckles for Temperatures up to 1000ºF for a Power Plant

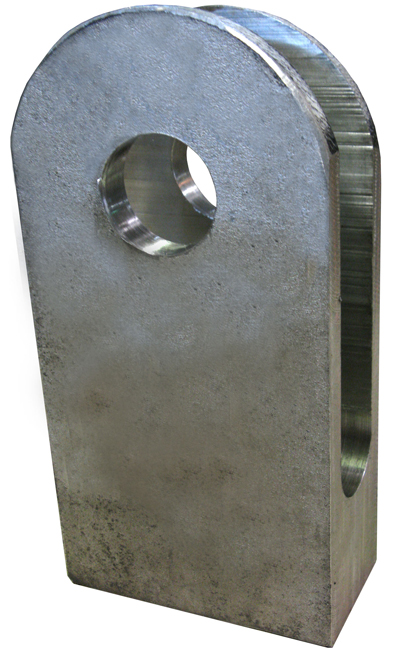

The clevis and turnbuckle pictured are each fabricated from individual solid pieces of 304H stainless steel. The 304H material, which has a maximum carbon content of 0.06%, was required because these items are designed to be used in an environment with temperatures up to 1000ºF. The customer’s specifications mandated that no welding would be allowed on either the clevises or turnbuckles. Additionally, no forgings were readily available, so blocks of 304H stainless steel were utilized in this design.

Both the clevises and turnbuckles are made to accommodate rod diameter ranges between 1-1/4″ to 1-3/4″. These components have a maximum load capacity of 18,600 lb. The clevises measure 3″ thick x 5-1/4″ wide x 10-5/8″ tall. The turnbuckles measure 2″ thick x 4″ wide x 9-1/4″ tall. Prior to fabrication, each component was modeled using finite element analysis to determine that stress levels are within the acceptable range.

Do you require some pipe support hardware for your project? Get pricing today!

Riser Clamp for a 30″ Diameter Vertical Pipe at a Power Plant

This carbon steel riser clamp is designed for an operating load of 22,400 lb. at 650°F, and has a hot-dipped galvanize finish. It is fabricated from 1¾” x 12″ bar stock with an overall length of 86″. PT&P has an extensive inventory of all types of pipe clamps made from carbon steel with galvanized or black finishes. Clamps from alloy steels for high-temperature applications are also available.

Do you see a need for riser clamps in your plant? Let us price them for you today!