Slide plates are designed to provide a low coefficient of friction between stationary structures and moving pipe supports. The plates provide a surface friction that has been carefully designed to allow for movements of the piping systems.

The slide plates allow the system to move with less force, keeping it in proper working order.

Assembly Basics of Slide Plates

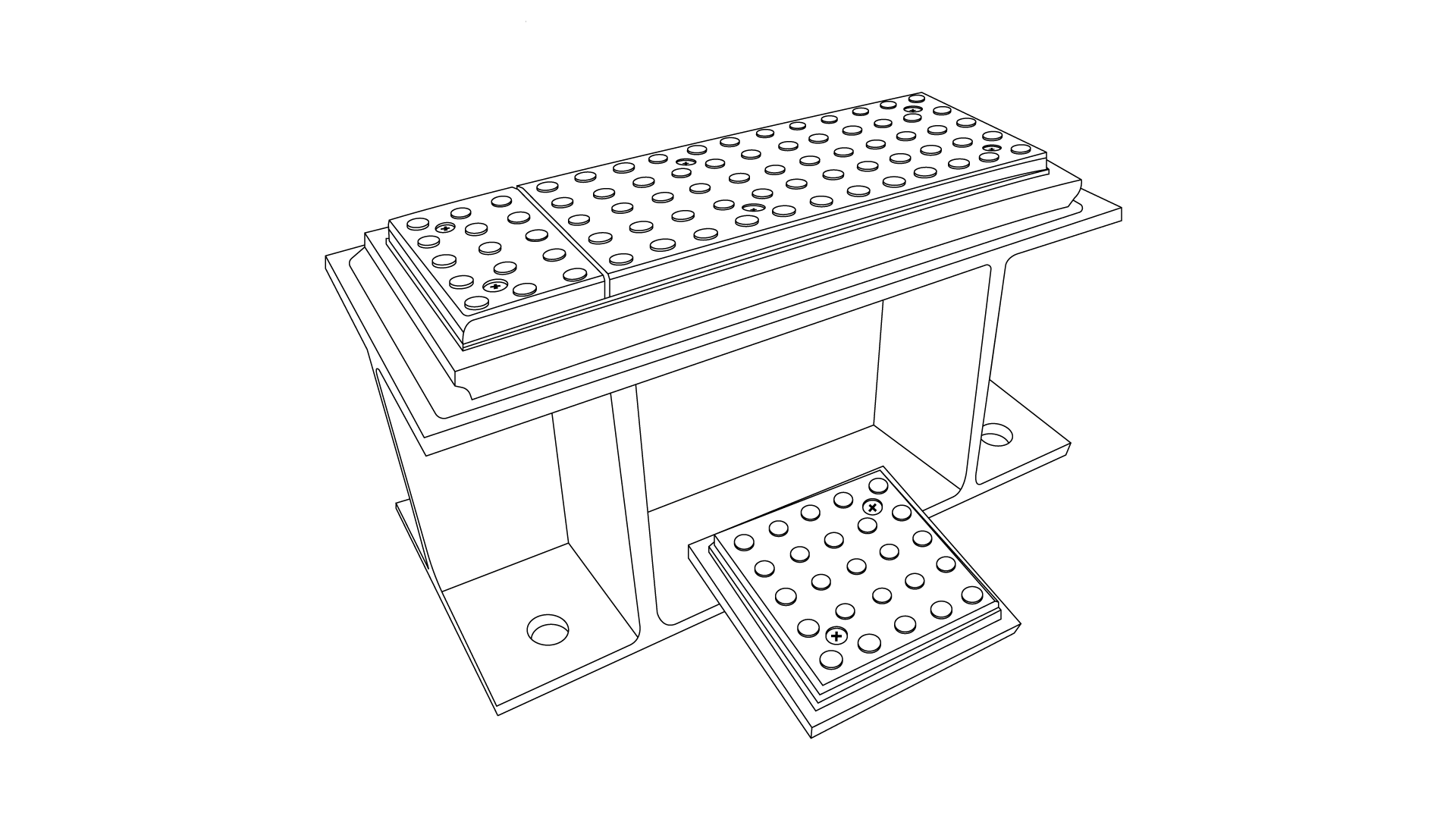

Slide plates are usually arranged in what is known as a ‘sandwich’ formation, which consists of an upper slide plate component and a lower slide plate component.

The lower slide plate may also be welded to a stationary support (i.e. structural steel member), which grounds the plate, while the other plate is attached to the moving component directly. As the system moves, friction is transferred at the intersection of the two plates.

When ordering, always specify the dimensions of the upper and lower slide plate. Generally, the upper slide plate should be large enough to cover the lower plate at all times.

Selecting the Right Slide Plate for Your Application

Different plates are suited for different temperature limits. While all slide plates have been rigorously tested for suitability within industrial settings, understanding the variables of that setting is vital to purchasing the appropriate plate for each application.

1. PTFE, 25% Glass Filled Slide Plates

These slide plates will handle temperatures from -320° F to +500° F.

The PTFE plates are ideal for cross-beam and girder slip joints, air preheaters, penstocks, vessels, and other industrial and architectural applications.

Installation of PTFE plates is available in two configurations: standard and custom. The standard assembly features two sets of 3/32” thick PTFE pads bonded to 1/8” carbon steel backing plates with a 1/2” lip for field welding. The custom assembly features 2 sets of 3/32” thick PTFE pads bonded to the specified backing material, with a minimum 1/2” lip for full welding.

If the desired thickness of the backing plate is not the standard 1/8,” those who are purchasing the plate should specify a different thickness when placing their order

2. Bronzphite® Slide Plates

Bronzphite® slide plates impregnated with graphite can operate in temperatures ranging from -320°F to +1100°F and withstand loads up to 5000 PSI.

The bronze slide plate is available in a standard configuration, consisting of a bronze plate bolted to a steel backing plate. The steel portion of the slide plate can then be welded in the field. Due to the graphite, the plate is self-lubricating and durable, making it suitable for various industrial applications, including pipelines, storage tanks, and dust collectors.

3. Graphite Slide Plates

Graphite can resist up to 3,000˚ F with 2000 PSI.

For those systems that produce exceptional pressure and heat, graphite slide plates are recommended. With a range of up to 1,000°F for ambient conditions and 3,000°F for inert settings, graphite slide plates can withstand pressures of up to 2,000 PSI.

The graphite plates are available in two different configurations: the ‘bonded’ and ‘bolted’ assemblies. The bonded configuration consists of a ¼” thick graphite pad bonded to a metal backing plate.

The bolted configuration consists of a ½” thick graphite pad bonded and bolted to a metallic backing pad. Both configurations can be tack welded or fully welded to support components.

Graphite plates are best for heavy infrastructures such as bridges, highway overpasses, railroad bridges, and airport hangar doors. Domes, roof slabs and corbels, vibration pads, and other architectural features are also suitable applications. In the industrial realm, offshore drilling rigs, wind tunnels, and other heavy machinery benefit from graphite plates.

4. Marinite Slide Plate

Marinite can be used as the insulating material in hot piping supports. Used in conjunction with stainless steel, Marinite is most often used as structural insulation because of its high dimensional stability.

Marinite is incombustible, provides high insulation values and high compressive strength, and is thus suitable for high-load and high-temperature applications. The material minimizes decay, rust, and corrosion, and it resists damage during installation, providing durable service.

The material acts as a suitable insulator in fireproofing and heat processing equipment applications up to 1200° F.

Conclusion

Slide plates are essential components in piping and structural systems, allowing for smooth, low-friction movement to accommodate thermal expansion and dynamic loads. With applications ranging from power plants to bridges, slide plate assemblies reduce wear, minimize maintenance, and enhance system longevity.

By selecting the right materials and configurations, slide plate applications can significantly improve performance in even the most demanding environments.

Ready to Order? Request a Quote Now