PT&P offers the most extensive line of pre-insulated supports that leverages PT&P’s engineering capabilities in material science and structural engineering. We have custom-engineered many solutions using a combination of FEA, thermal analysis, and material engineering. View our pre-insulated support product archive gallery.

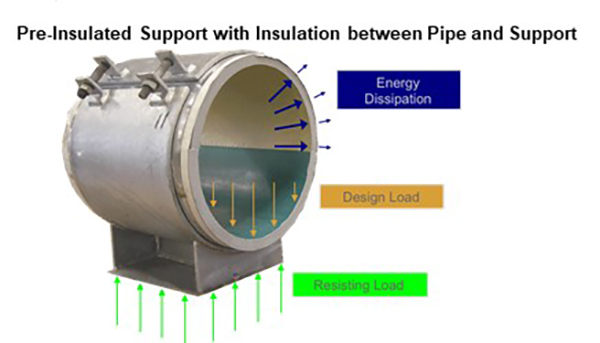

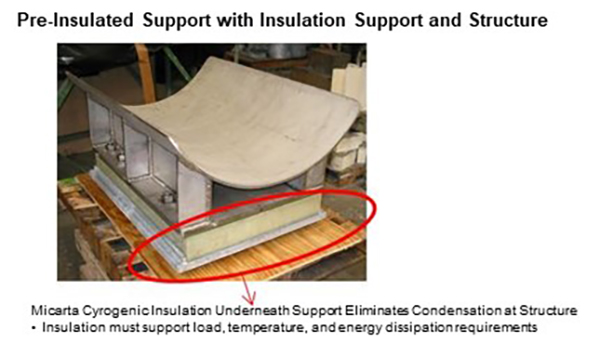

There are two approaches to pre-insulated shoes, as shown below. You can either insulate between the pipe and the pipe support or you can insulate between the pipe support and the structure.

|

|

Key design considerations on an overall design include:

- Temperature limits which must be supported

- Energy which must be dissipated

- Ensuring condensation is not formed which would cause corrosion

- Ensuring temperatures of exposed areas remain below maximum temperature allowed by plant safety

- Cost of the design

- Longevity of insulation supporting the required load, temperature, and energy dissipation

- Allowable space for overall support

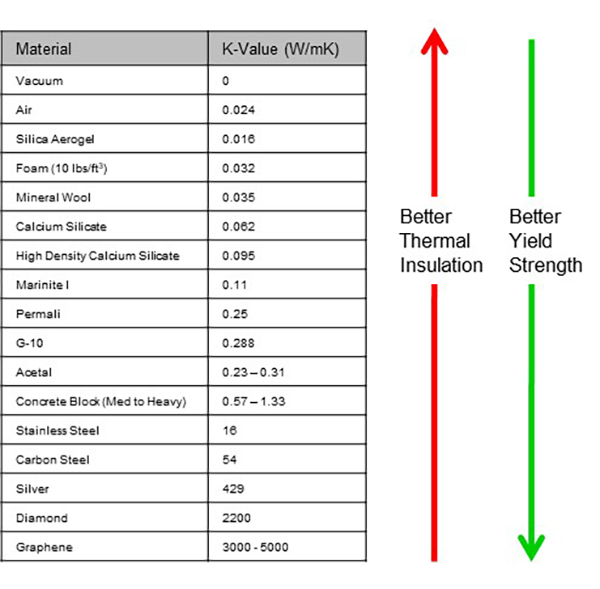

Insulating pipe supports is more challenging than insulating pipe. The reason is that pipe insulation is not required to bear the load of the pipe. With pipe support, the load of the pipe must be supported. The reason this is challenging is that insulation efficiency tends to be inversely related to compressive strength. The table below shows the k-value or thermal conductivity of a variety of materials.

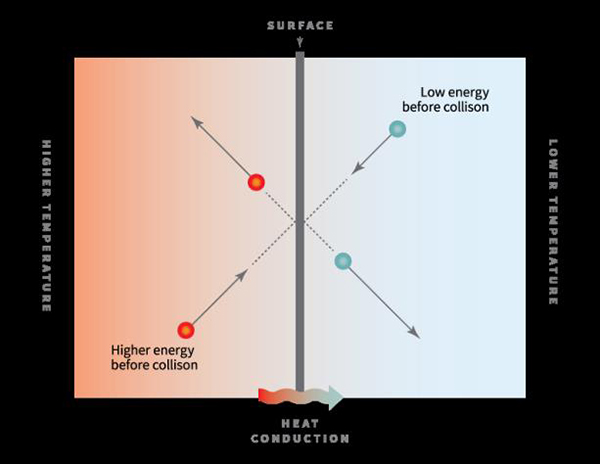

The challenge with insulation and compressive strength is that molecules are transmitters of energy. As the graphic on left below, collisions between molecules are what allow the transfer of energy. Hence, the density of molecules, in general, allows for greater transmission of thermal energy. This is why a vacuum is a perfect insulator as it offers no molecules which can be used to transfer thermal energy.

|

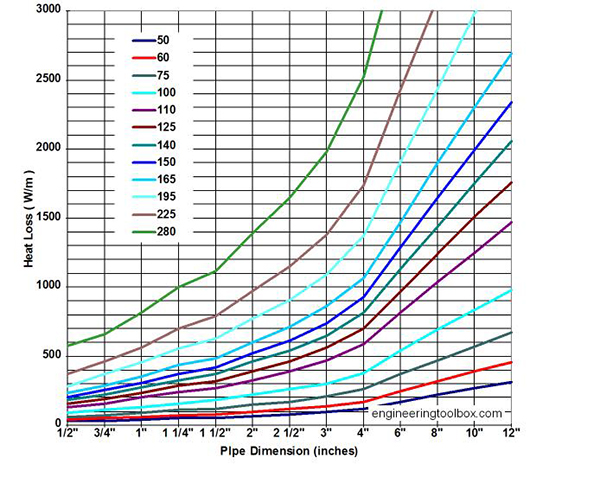

In addition to insulation limiting the thermal energy transferred to the pipe support or structure, exposed steel loses thermal energy to air. For example, the chart below heat loss from steel pipe based on the pipe dimension and temperature difference between the pipe and air. Under MSS code, steel supports lose 100° F per inch as measured from the outer wall of the pipe.

|

Below is a photo of corrosion due to condensation at a support location. This is an example of the issues that can arise when insulation is not properly engineered.

PT&P offers a complete range of capabilities for insulation, including:

- Pre-Insulated Supports – PT&P is the global leader in pre-insulated supports for both hot and cold applications.

- Custom Pipe Support Design – PT&P can custom-design pipe supports, taking into account structural issues, space limitations, special material requirements, and management of thermal issues.

Case Study #1

PT&P received the cryogenic pipe support design from a major EPC for a large LNG project. After receiving the design, PT&P became concerned with the performance of the design based on its experience with cryogenic pipe supports. Our engineers ran FEA and thermal analysis, which showed the design would meet the requirements for the project. PT&P set up and executed a cryogenic test at its facility and reviewed its calculations with the customers. Based on this feedback, the customer changed the support design for a multi-billion-dollar project.

Case Study #2

PT&P was requested by a customer to determine the optimal insulation choice and thickness for a chilled water line. PT&P provided the customer with a range of potential options for insulation. Once the customer had determined their insulation preference, PT&P ran the calculations to determine the required insulation thickness for the line.