Piping Technology & Products designed and fabricated 107 variable spring hanger assemblies for an Oil Sands Expansion Project in a central processing facility in Canada. We fabricated these C-type variable springs from hot-dipped galvanized carbon steel. The design loads range from 3,343 lb. to 3,417 lb., and each assembly underwent a series of tests and detailed quality control inspections prior to shipment.

Variable Spring Hangers Designed for an Oil Sands Expansion Project

test service nolan

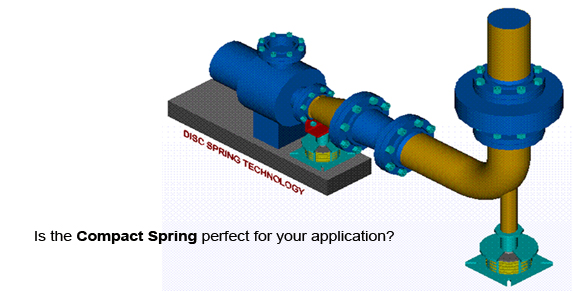

The compact spring is ideal for applications with large loads and limited space.

The compact spring is ideal for applications with large loads and limited space.