Download PDF

Piping Technology & Products, Inc. is a manufacturer and fabricator of all types of pipe supports. This section is devoted to variable spring and constant supports. In addition to the many standard supports you will find described here, we will design and custom-build special supports to meet your specific needs. In fact, many of the items you will see in this catalog were developed for the specific requirements of a customer who could not use the standard designs available in our industry. If you do not find what you need, or if you need technical advice, please contact us.

Designers of piping systems must provide for the pull of gravity and for movement due to thermal expansion. Spring supports, variables, and constants are devices which are cost-effective and structurally sound in solving certain pipe support problems. Constants are more expensive, so they are usually used in more critical applications, described in detail in the Constant Spring Hangers section.

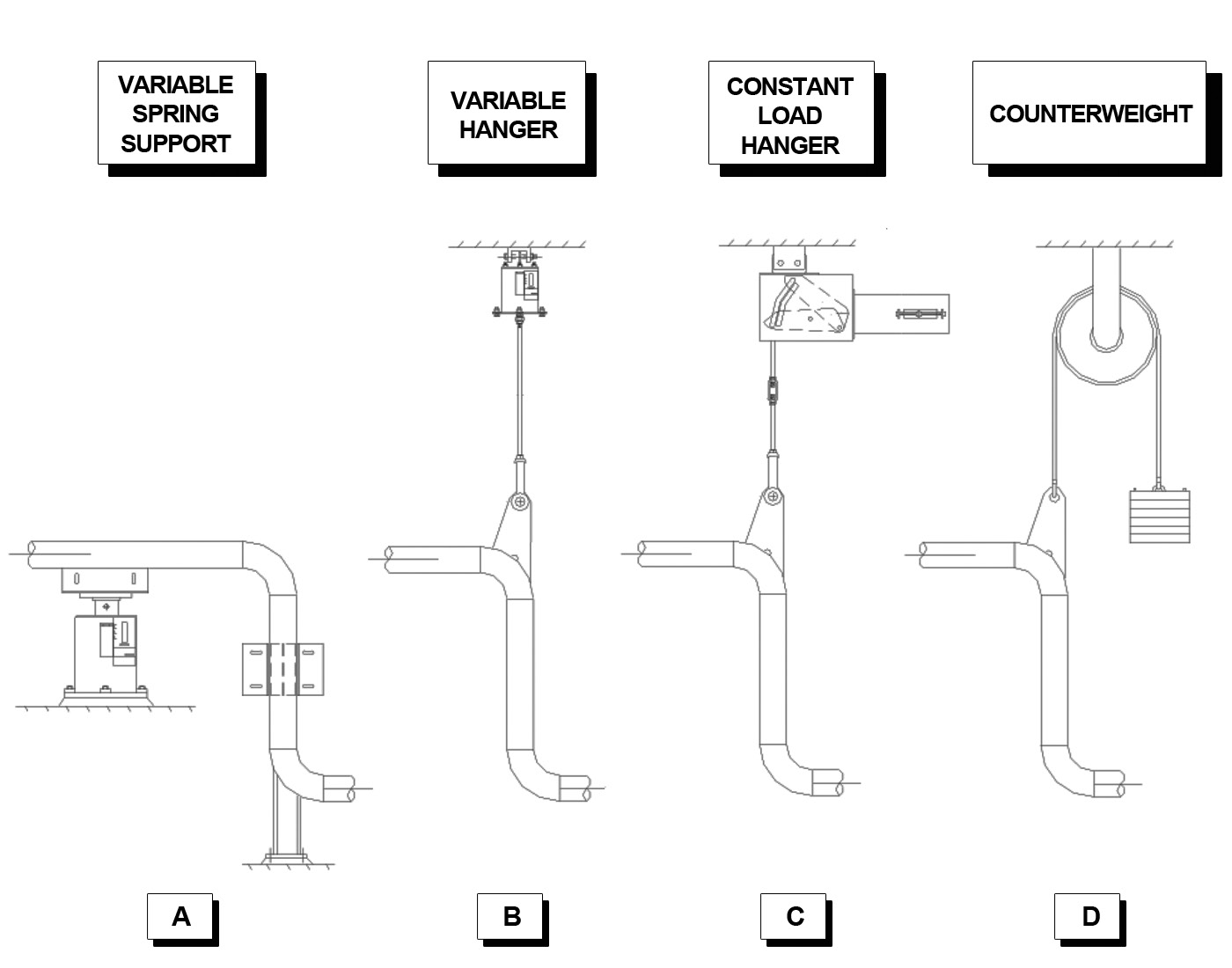

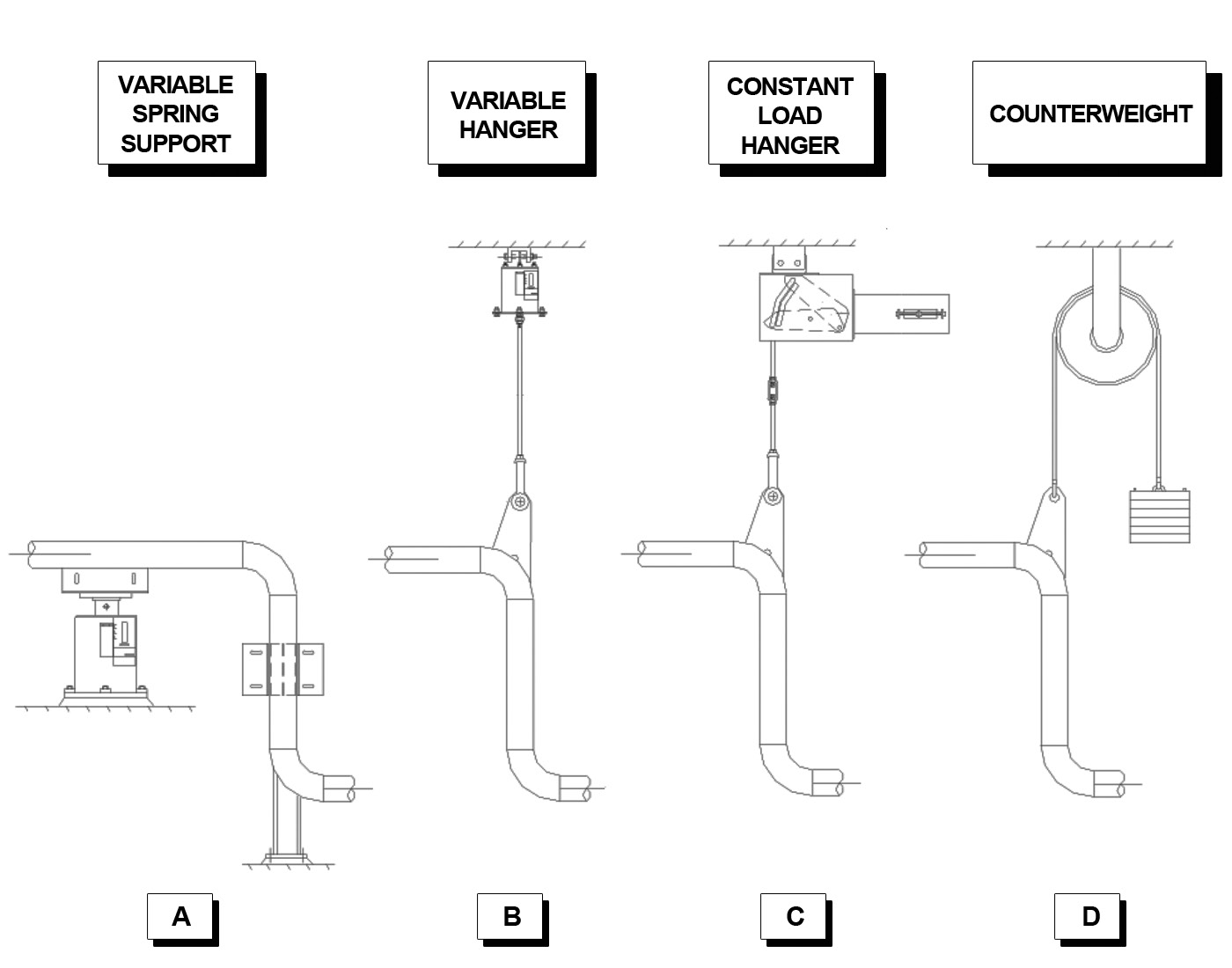

The illustration below shows three applications of spring supports and one involving a counterweight. In figure (A), a variable spring support is placed under the horizontal pipe just left of a vertical section which has a guide and rigid support. In (B) a variable hanger is suspended from above and connected to the elbow above the vertical section. In (C) the designer has chosen a constant load hanger because the vertical section is connected to a critical nozzle. A counterweight such as shown in (D) may be useful when pipe weights are unknown and must be balanced in the field. Piping Technology & Products, Inc. will calculate and custom-fabricate such counterweights for you.