| Type: | Variable Spring Supports with Clevis Hangers |

| Material: | A36 Carbon Steel | 304 Stainless Steel |

| Design: | 800°F | 619 lb. Ld. | 0.5″ Up Travel |

| Testing: | Load and Travel Tests |

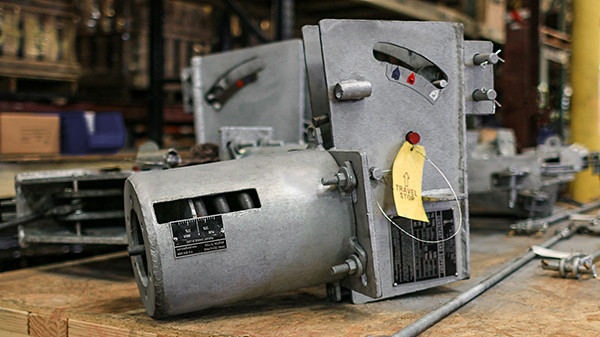

Piping Technology & Products designed these B-Type variable spring supports with clevis hangers for an ethylene cracker plant in Texas. Interestingly enough, we recently supplied over 50,000 supports to one of the largest ethane cracker polymer plants in the US, which was completed last year. In addition to variables, we supplied slide bearing plates, hot and cold insulated shoes/supports, snubbers/sway braces/sway struts, pipe hanger hardware, expansion joints metal bellows, rectangular & circular spacers, davit arms, welded pipe shoes, rod hanger assembly, and wear Pads

On this client order, the variable spring supports, threaded rods, and hex nuts were fabricated from A36 carbon steel, and the clevis hangers from 304 stainless steel. The assemblies are 83-1/8″ in length, and the spring size is 6-80-B. They are designed for an operating temperature of 800°F, an operating load of 619 lb, and 0.5″ of movement. Standard load and travel tests were performed prior to shipment.

PT&P REF. ORIGINAL POST 06052018