If you manage a process plant, power facility, or oil and gas operation, you know that piping systems are at the center of your entire operation. But how often do you think about the hidden forces: the intense pressures, temperature shifts, and vibrations that are constantly pushing your pipes to their breaking point?

Ignoring these forces isn’t just a risk; it’s a guaranteed path to costly downtime, failures, and safety hazards. This is where pipe stress analysis comes in: it’s the essential engineering practice that ensures your piping system not only works but lasts.

What Exactly is Pipe Stress Analysis?

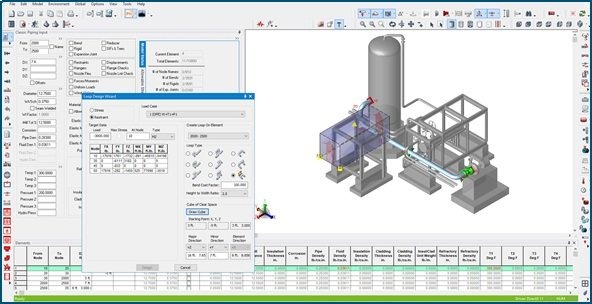

CAESAR II PSA

Pipe stress analysis is a systematic, mathematical study used to evaluate the stresses and displacements in a piping system. Think of it as a comprehensive health check-up for your pipes.

An engineer uses specialized software to build a virtual model of your entire system. They then subject this model to all the real-world conditions it will face:

- Pressure: The internal force from the fluid or gas being transported.

- Temperature: The thermal expansion and contraction that occur as the fluid’s temperature changes (often the single biggest source of stress).

- Weight: The dead weight of the pipe, fluid, and insulation.

- External Loads: Forces from wind, seismic activity (earthquakes), or external equipment (like pumps or valves).

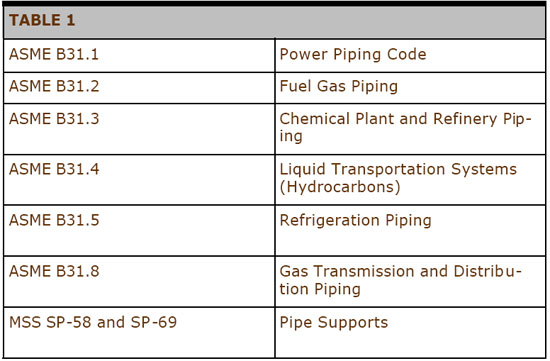

The goal is to verify that the stress imposed on the pipe wall, fittings, and supports remains within the limits defined by industry codes, such as ASME B31.3 for process piping.

Why Is This Analysis Critical for Your Operation?

Skipping or shortchanging pipe stress analysis is a classic example of being penny-wise and pound-foolish. The costs of a failure far outweigh the cost of analysis.

1. Prevent Catastrophic Failure and Leaks

The most immediate benefit is safety. Excessive stress can lead to fatigue cracking, flange leaks, or even a sudden rupture. Analysis ensures that your system can handle every operational scenario without a catastrophic failure that endangers personnel and the environment.

2. Protect Expensive Equipment

Piping doesn’t exist in a vacuum; it connects to critical, often multi-million-dollar equipment such as pumps, turbines, and heat exchangers. If a pipe expands excessively and pulls on a connected nozzle, it can cause severe damage or destruction to that equipment, resulting in substantial replacement costs and prolonged downtime.

3. Ensure Reliability and Uptime

A properly analyzed and supported system experiences less vibration, less wear on supports, and fewer flange leaks. This directly translates into higher operational reliability, minimizing unexpected shutdowns —the biggest drain on a plant’s profitability.

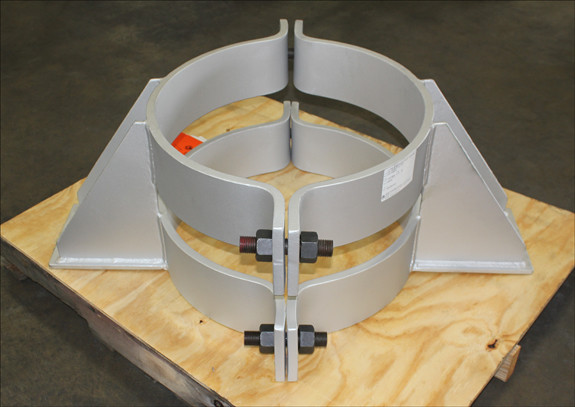

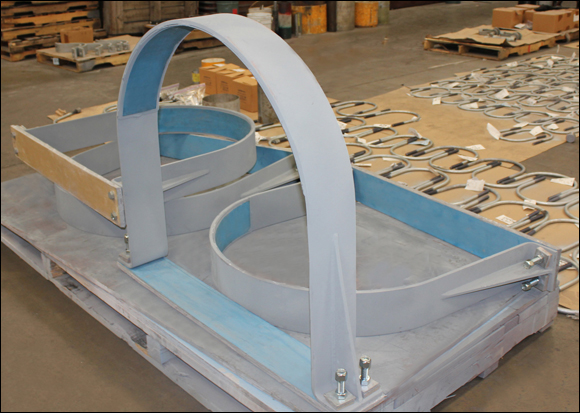

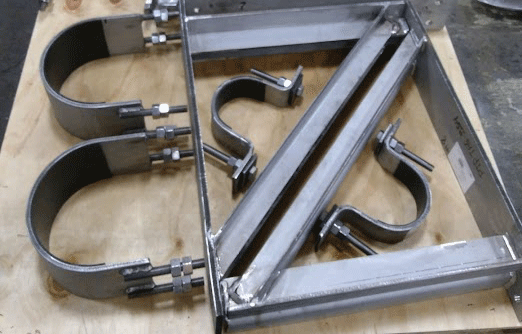

4. Improve Support Selection

This is where analysis meets reality. Once the stress engineer knows where the forces are greatest, they can correctly design and specify the right supporting elements. Are standard clamps enough, or do you need specialized solutions such as pipe shoes, slides, or anchors to manage movement and transfer loads safely to the structure?

Pipe Stress Analysis Software

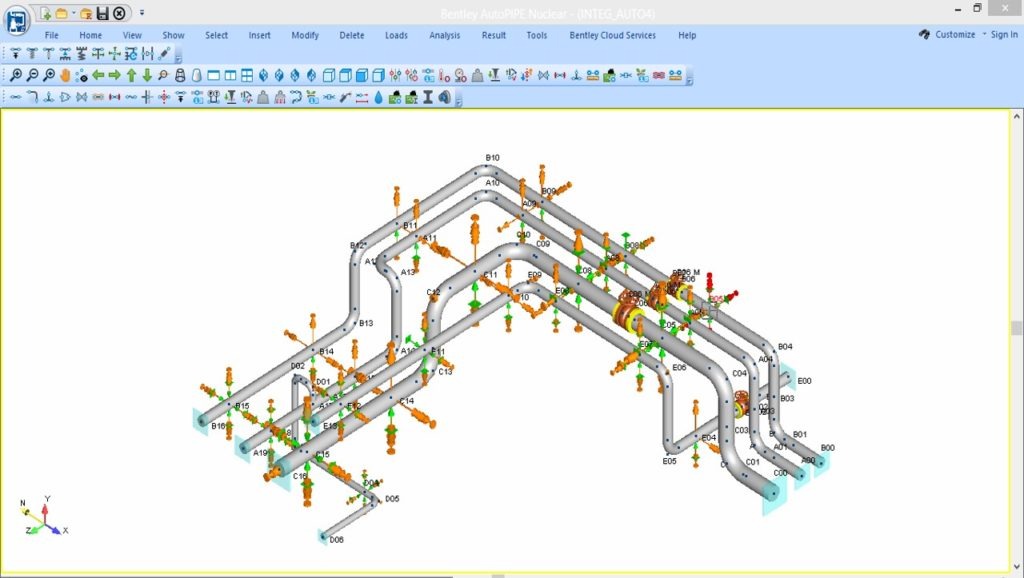

AutoPIPE PSA

Performing a thorough pipe stress analysis is a task too complex and iterative to be done manually. Specialized pipe stress analysis (PSA) software is essential for creating detailed virtual models, applying various load cases, and performing the millions of calculations required to comply with industry codes.

These sophisticated programs allow engineers to:

- Rapidly model complex pipe routing, components (valves, fittings), and support structures.

- Accurately simulate real-world conditions like thermal expansion, seismic events, wind load, and transient conditions (e.g., water hammer).

- Automatically check results against stringent design codes (e.g., ASME B31.3, B31.1) to confirm compliance.

A few key players dominate the market, each offering powerful tools with slightly different specialties and features. The most recognized and widely used software packages globally include:

- CAESAR II (Hexagon): Arguably the industry standard, known for its extensive code compliance checking and user-friendly interface.

- AutoPIPE (Bentley Systems): Highly capable, often praised for its integration with CAD and structural analysis programs.

- CAEPIPE (SST Systems): A well-established tool favored for its speed and intuitive graphical user interface (GUI).

Selecting the right software is crucial, as its accuracy and features directly impact the reliability of your final design. The results of this virtual analysis guide real-world decisions about where and how to place the critical pipe supports.

The Support Solution is Key

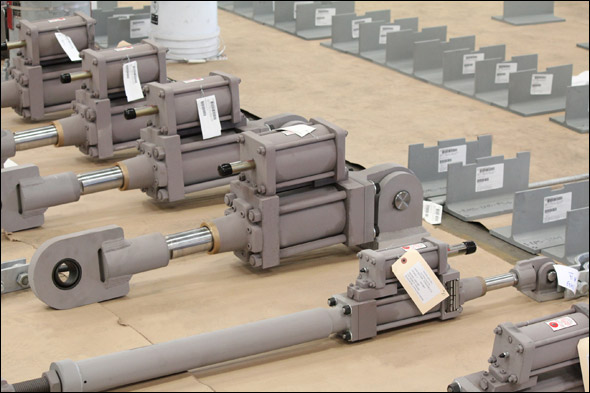

Stress analysis identifies the problem, but pipe supports are the engineered solution. If a study shows excessive movement or load on a critical elbow, the correct support, chosen for its material, design, and load capacity, is essential to resolve the issue.

At Pipe Shields, we specialize in high-quality, engineered supports that implement the findings of your stress analysis. We turn theoretical safety into physical reliability. By using the right shields, slides, and clamps, you ensure that the structure in the field safely manages the stresses calculated in the model.

Your Piping System Can’t Talk, But Our Piping Technology Team Can Read Its Stresses

Pipe stress analysis is the first step to guaranteed piping integrity. It’s not just a compliance checkbox; it’s a fundamental investment in your plant’s future.

Piping Technology & Products (PT&P) is the essential physical assurance against the high costs of piping failure.

After your pipe stress analysis identifies critical stress points, we provide the precisely engineered supports (pipe shoes, guides, slides) that safely absorb and dissipate those forces, protecting your multi-million-dollar equipment and protecting your investment in piping infrastructure. Get started with a PT&P pipe stress analysis now.

Don’t wait for a leak or a failure to realize your piping system is under-designed. Speak with one of our experts to receive a customized quote to improve safety and extend the lifespan of your piping system.