- Cost effective

- Easy to move

- Compact folding function for storing

- Minimal set-up for convenient access

- Includes bulletproof riot shields rack for placement/storage

- No maintenance required

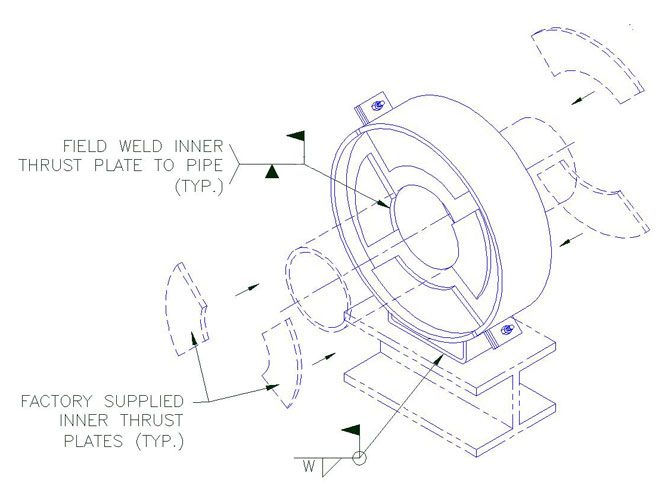

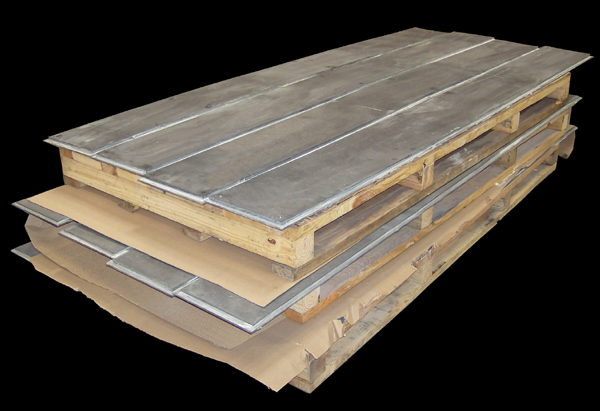

PT&P designed and fabricated a full coverage bulletproof shield for a company in Texas. This critical defense product is cost-effective, easy to move, compact to store, and convenient to access at a moment’s notice. Each unit includes slots in order to store four bulletproof riot shields. We hope the need never arises; however, this safety product is suited for public spaces such as schools, churches, concerts, public events, government agencies, and functions. The shield can function as a cover for a doorway providing safety to inhabitants while also allowing for mobility enabling persons the ability to exit safely from an unforeseen situation. The key design considerations this shield sought to address were safety of the defense personnel by providing for head to toe protection but also enabling mobility during one onto one incidents.

In addition to our deep technical expertise in the design and manufacturing of supports and expansion joints for piping systems, we have always been able to pivot to build what is the task in the moment by our customers and community. The bulletproof shield showcases our ability to be flexible, think outside of the box, and solve most problems.

Some of our key products, such as the big ton, are a product of this kind of exchange with our customers. We invite you to take a look at your project needs and our scale and capabilities and ask what we can do for you.